The Ruhuna as a region from ancient times was known as ‘Dakshina Deshaya’ and Hambantota is identified as an important city in Dakshina Deshaya. Historic evidence found in places like Ussangoda and Pallemalala within the district of Hambantota bears testimony to the existence of human settlements several thousands of years before the 5th century BC. Historically and culturally, the most significant area in the Hambantota district is Magampattu. During the British occupation, a separate district was carved out for Hambantota because of its strategic importance.

In developing Hambantota as an industrial enclave, the infrastructure, amenities, financial institutions and so on are being upgraded. The present regime seeks the participation of the private sector in this development effort.

The Ruhuna used traditionally produces a wide variety of crops. Hambantota is known for its potential in the agricultural sector and in traditional economic activities. The district of Hambantota is earmarked as a special enclave for economic development because of its natural resources and climate.

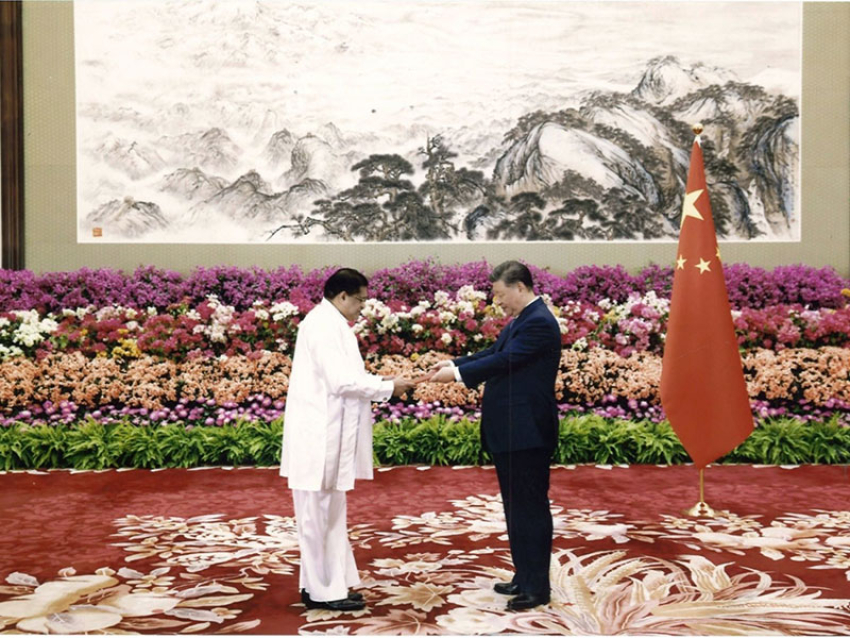

The district of Hambantota will see a transformation in almost all spheres under the leadership of President Gotabaya Rajapaksa and Premier Mahinda Rajapaksa. Their Government is involved in promoting this vibrant southern region of Sri Lanka as an economic enclave with the participation of the private sector. The potential of Hambantota has not yet been fully explored. It is up to local and foreign investors to reap the full benefits of this untapped potential. Hambantota is known for its salterns and production of salt.

The present administrative district has a district secretariat and is divided into 12 divisional secretariats. President Gotabaya Rajapaksa’s Government has directed its attention to ushering in rapid development in the area.

The salterns in Hambantota are the biggest of its kind in Sri Lanka. The Bundala salterns – Maha Levaya and Palatupana Levaya – are important salterns in Hambantota. The salt produced here is provided to consumers under the label ‘Lak Lunu’. Hambantota Maha Levaya was under the management of a department in 1938 and was converted to a corporation in 1957 with the amalgamation of three salterns: Maha Levaya, Bundala and Palatupana.

The tsunami that swept across the Hambantota salterns in 2004 caused extensive damage to the salt beds. Long-standing layers of salt were destroyed and as a result, the expected salt harvest could not be obtained in 2005 and in 2007, the salt harvest was at its lowest. In 2008, the estimated salt harvest was 68,500 metric tons, but due to climatic changes, only 77,000 metric tons were obtained, the Lak Lunu production manager said.

The Hambantota salterns were developed under the ‘Lunu Nagara’ or Salt City project several decades ago. Under the project, an administration complex, a salt museum, a high quality research centre and a field office were opened in 2006.

Salt is an essential commodity for a meal. If a meal is without the required quantity of salt, it is not tasty, even after adding spices. Tradition has it that a pot of salt and a pair of buffaloes was given as dowry when a girl was given in marriage, because salt is such an important commodity.

Salt is produced by evaporating seawater and using the sodium chloride that is left after the evaporation.

The Lak Lunu production manager said that only an acre of salt could be obtained after filling 10 acres of salt beds with seawater. After the harvest, the salt which is then yellow in colour is left exposed to the sun for a period of three months to be purified into white salt. Trucks of salt are then brought to the salt production unit where gravel stones, sand, clay and pieces of iron are removed. A huge magnet is used for the separation of tiny pieces of iron. Afterwards, the salt is ground to the size of 3.3 metres.

The third stage is the washing of salt and drying in large-scale dryers. It is then that the salt is iodized. The labourers at the salterns have to work in any type of weather. Salt produced at the Hambantota salterns bears the ISO 2000 quality standard and the SLS badge. The production manager said that the Hambantota salterns produce 60 percent of the country’s production of salt, while the Puttalam salterns produce 40 percent.

The iodized salt is issued to the salt packing agents in bulk; there are a large number of salt packing agents in the district and outside. The agents sell packets of salt at a price lower than that of the state’s Sri Lanka Salt Ltd, and as such, there is a good demand for the salt packed by the private sector agents.

Thousands of people are engaged in salt packing as a livelihood. Most of the unemployed educated youth in the Hambantota district engage in the salt packing, having obtained loans from banks and lending institutions, as a means of self-employment. The requirement of salt for the entire country is 120,000 tons and the import of salt is essential to cater to the demand as local production is not enough, the production manager said.